Impedance Measurement

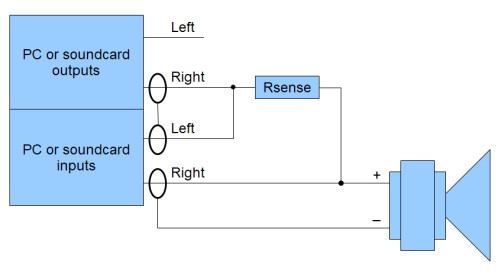

REW can make measurements of impedances up to a few hundred ohms by using both inputs of the soundcard. Impedance measurements of drive units can be used to calculate the Thiele-Small parameters. The general connection arrangement for impedance measurements is shown below:

The sense resistor, which must be non-inductive, is used to measure the current flowing into the load, which will be (Vleft - Vright)/Rsense. The sense resistor should have a power rating sufficient to cope with a short circuit load and have a low temperature coefficient. The voltage across the load is Vright, so the impedance is nominally voltage/current = Rsense*Vright/(Vleft - Vright). Note that prior to completing the calibration process the accuracy of impedance measurements is only as good as the accuracy of the value entered for the sense resistor.

The load appears in parallel with the input impedance of the soundcard and the impedance of the test leads. Before calibration those effects are partially corrected for by using the parallel equivalent of the sense resistor and soundcard input resistance in the calculation, the soundcard input resistance figure is entered on the dialog as RINPUT.

Good results can be obtained using a headphone output (or, even better, a good headphone amplifier or a device with a high power headphone output) to drive the load, with a 100 ohm sense resistor. If a line output is used the sense resistor typically needs to be larger as line outputs have high output impedance and limited drive capability, try 1 kohm but note that the results will have much higher noise levels and be more susceptible to background noise. If the device being used to drive the load can cope with lower loads a lower sense resistor, 47 ohm for example, will improve the results.

An alternative is to drive the load via a power amplifier, which can deliver the lowest noise levels and most accurate results, but great care must be taken as the levels a power amplifier can generate can easily damage soundcard inputs. If using a power amplifier the sense resistor can be much lower, 33 ohms or less, but the soundcard inputs should be connected via a resistive divider providing around 20dB of attenuation and ideally the inputs should also be protected by back-to-back zener diodes to clamp the input to less than 5V.

The soundcard input connected to the load must be the same one which has been chosen as the input in the REW soundcard settings. In the diagram above that is the right input, but if the left is being used simply swap left and right in the diagram. If the left and right connections are the wrong way around the impedance measurements will show curves that are shifted up by approximately the value of the sense resistor.

The input channels should have the same gain. If the audio interface has individual channel gain controls adjust them to have the same gain before starting to measure. An easy way to do that is to connect the impedance rig with the test leads left open and use the signal generator to play a sine tone at 1 kHz at the intended measurement level while observing the input levels on the Level meters. Adjust the input gains so the input and reference channel levels match to within 1 dB and are not clipping.

Sweeps of 10 seconds or longer are recommended for impedance measurement to provide good signal to noise ratios in the results.

Calibrating the Impedance Rig

To get the most accurate results the impedance measurement rig must be calibrated. The calibration can remove the effects of small gain differences between the soundcard input channels, differences in the frequency responses of the channels, and the impedance of the test leads. Three measurements are needed to fully calibrate the rig, but as a minimum the first (open circuit) calibration measurement should be performed. REW automatically saves calibration data from each measurement in the REW log files directory.

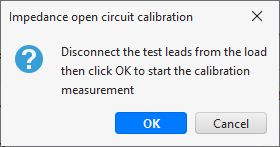

Open circuit calibration

The first step is to calibrate the measurement rig with the test leads open. They should still be connected to the rig, but left open at the load end. This measurement compensates for gain differences between the input channels.

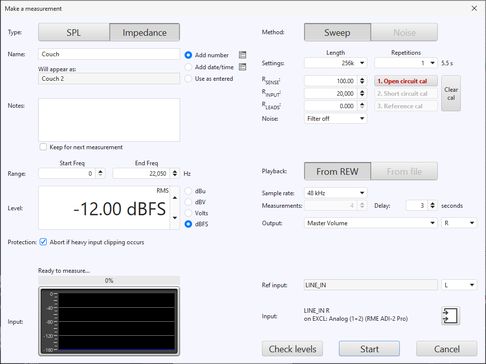

- Press the Measure button (or Ctrl+M) to bring up the Measurement panel, select the Impedance button and press the Open circuit cal button - the button text is red if impedance calibration has not been done. Disconnect the test leads at the load end as prompted before clicking OK on the prompt to start the measurement.

- The completed measurement shows the level of the measurement channel (usually right) compared to the reference channel, where a reading of 100 Ohms corresponds to 100%, 99 Ohms would be 99% etc. If the difference between the 2 channels is too large (more than 2 dB) the calibration is abandoned as it is likely there is a connection error or the input channels have different gain settings, re-check the connections and channel gains and try again.

- After the open circuit calibration gain differences between the input channels will be corrected.

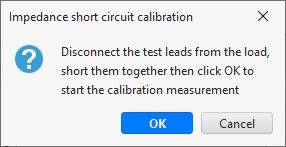

Short circuit calibration

The second step is to calibrate the measurement rig with the test leads shorted. They should still be connected to the rig, but shorted together at the load end. The measurement compensates for the series impedance of the test leads, it particularly improves high frequency accuracy. If this measurement is not carried out the RLEADS box can be used to compensate for the test lead resistance. After this measurement the RLEADS box is hidden since it is no longer used.

- Press the Measure button (or Ctrl+M) to bring up the Measurement panel, select the Impedance button and press the Short circuit cal button. Short the test leads together at the load end as prompted before clicking OK on the prompt to start the measurement.

- After the short circuit calibration the series impedance of the test leads will be calibrated out.

Reference resistor calibration

The third and final step is to make a measurement of a known reference resistor. The reference resistor must be non-inductive and its precise value must be known, errors in the reference resistor will translate directly into impedance measurement errors since it is used to scale all subsequent measurements. It should have a value around that of the impedances to be measured, for speaker impedance measurements a reference of 100 ohm or lower is recommended. The reference resistor measurement compensates for frequency response differences between the input channels. It particularly improves accuracy at the frequency extremes. After this measurement the RINPUT box is hidden since it is no longer used.

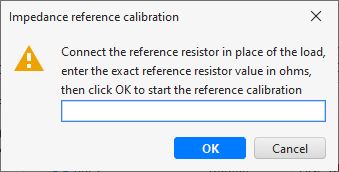

- Press the Measure button (or Ctrl+M) to bring up the Measurement panel, select the Impedance button and press the Reference cal button. Connect the reference resistor to the test leads before entering its exact value and clicking OK on the prompt to start the measurement.

- After the reference resistor measurement calibration is complete.

The calibration data is saved in the REW log files folder and automatically loaded when REW starts up. If the test leads are changed (swapped for longer or shorter leads, for example) or the sample rate is changed the calibration steps should be repeated.

Making an Impedance Measurement

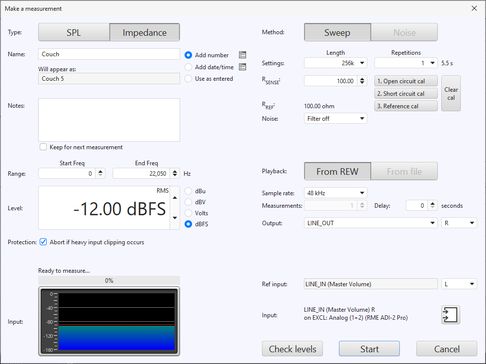

- Press the Measure button

(or Ctrl+M) to bring up the Measurement panel and select the Impedance button

(or Ctrl+M) to bring up the Measurement panel and select the Impedance button

- Enter the exact value of the sense resistor. This must be measured accurately with a good quality, calibrated multimeter or impedance bridge, or a very high precision resistor (0.1% or better) should be used. Any error in the value of the sense resistor directly affects the measurement results.

- Set the Start Freq to the lowest frequency for which you wish to see the response and End Freq to the highest. If measuring a drive unit to determine its Thiele-Small parameters measure up to 20 kHz. The sweep will span the range from half the start frequency to twice the end frequency (with an overall limit of half the soundcard sample rate) to provide accurate measurement over the selected range.

- Level controls the rms signal level at which the sweep is generated. The maximum value is -3 dBFS or its equivalent in dBu, dBV or volts, unless the View preference Full scale sine rms is 0 dBFS has been selected, in which case the maximum is 0 dBFS. Using the maximum value places the peaks of the signal at digital full scale - some soundcards may distort at the maximum level. If you are using a power amplifier beware of excessive levels. Loudspeaker impedance is typically best measured at a terminal voltage of around 100 mV to 200 mV at most, the output voltage to achieve that depends on the sense resistor value. For a 100 ohm sense resistor and an 8 ohm driver the output for 100 mV at the terminals would be around 1.35 V.

- Settings for the measurement method are on the right hand side. Length controls the length of the sweep, specifying the number of samples in the sequence. The default is 256k. Dividing the number of samples by the soundcard's sample rate gives the sweep duration in seconds, shown to the right. The overall duration includes silent periods before and after the sweep.

- If Sweeps is more than 1 REW uses synchronous pre-averaging, capturing the selected number of sweeps per measurement and averaging the results to reduce the effects of noise and interference. The pre-averaging improves S/N by almost 3dB for each doubling of the number of sweeps. Averaging is particularly useful if the measurements are contaminated by interference tones, whether electrical or acoustic, as they typically will not add coherently in the averaging and hence will be suppressed by the process. The output and inputs must be on the same device if using multiple sweeps.

- The Check Levels button generates a few seconds of a pink noise signal that spans the frequency range selected for measurement and checks that the input level is not too high or too low. Pressing Cancel while the pink noise signal is playing will turn it off (it turns off automatically after 3 seconds). The rms level that was measured is shown on the measurement panel, with a warning if the level is too high or too low.

- Press Start to make a measurement, progress is shown on the measurement panel along with a display of the measurement headroom.

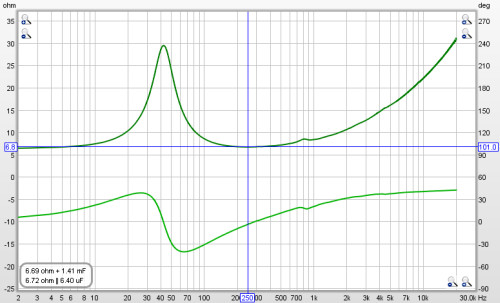

The result of the measurement is displayed in the graph area, information about the measurement appears in the Measurements Panel. Measurements are given a default name of the date and time at which they are made, a more appropriate name can be entered in the box at the top of the measurements panel.

For impedance measurements when the mouse cursor is within the graph panel the equivalent series resistance + inductance or resistance + capacitance and parallel resistance||inductance or resistance||capacitance of the impedance at the cursor position is shown at the bottom left corner of the graph. This may be useful when making measurements of inductors or capacitors to check their value, but the Component Model provides a much more accurate equivalent circuit.

For details of the various ways of viewing the measured data, including averaging multiple measurements, refer to the Graph Panel help.

Input Channels Swapped

If the input channels have been connected the wrong way around the impedance measurements will be too high by approximately the value of the sense resistor, make a test measurement of a resistor (of less than 100 ohms) to check that everything is wired correctly. Swapped channels will also shift the phase by about 180 degrees.

Impedance Measurement Quality

The main source of measurement noise is acoustic noise and vibration during the measurement. Loudspeakers act as microphones, generating small voltages in response to sounds and vibrations that are picked up as part of the load voltage. To minimise this effect use long sweeps, low sense resistor values, avoid noisy environments and isolate the loudspeaker from vibration. Using a power amplifier to drive the speaker provides a much lower drive impedance, which reduces the effect of noise, and allows a low series resistor to be used.

REW provides a Noise filter option which applies a bandpass filter to the captured sweep, synchronised to the sweep frequency, to reduce the influence of noise. The High setting is suitable in most circumstances, but it may have a slight smoothing effect on very sharp resonances. If that is observed try the Medium or Low settings, or turn the filter off. When the filter is being used the sweep duration should be at least 10 seconds, a warning is shown if a shorter sweep is selected. Longer sweeps improve signal to noise ratios in the results with or without the noise filter.